Bal-tec™ Home Drilled and Threaded Kinematic Balls

Threaded Kinematic Balls

A very sound approach for rigidly holding the spherical components on a Kinematic Platform is to use drilled and threaded balls. The drilled and threaded balls have gained great popularity of late. This surge in popularity is based on the results of some recent kinematic research that indicates that a ball glued into a mating spherical cup is a very good, and may even be the best way to mount a ball. The ball is held rigidly in position by a thin glue joint. This design has high shear resistance, as the ball is buried in the recessed spherical cavity. It can not torque due to the threaded shank of the holding screw. In addition, it is insensitive to hygroscopy of the glue because there is almost no exposure of the glue line to the atmosphere.

Standard drilled and threaded balls are offered in micro grain stainless steel that is hardened to 58 HRC minimum or in extremely stiff tungsten carbide with a Young's Modulus of Elasticity of 98,000,000 PSI and a very high hardness of 91 HRA making it the hardest, most rigid, material commonly available.

In addition to the standardized designs, we will custom manufacture drilled and threaded balls in any size and of any material to suit specific customer needs. These variations may include such properties as corrosion resistance and desirable magnetic or electrical properties.

| Part Number Stainless Steel |

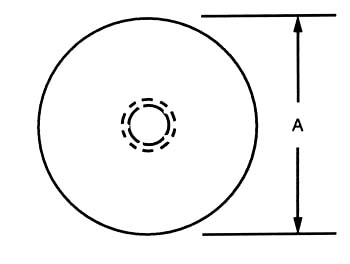

A- Diameter ± .0001 |

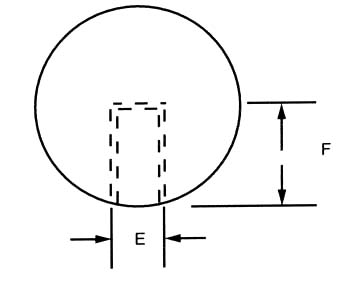

E - Thread Minimum |

F - Depth |

|---|---|---|---|

| 312-B-T | 3125" 7.9375 mm |

#6-32 | .150" 4mm |

| 375-B-T | .3750" 9.525 mm |

#10-32 | .200" 5 mm |

| 50-B-T | .500" 12.700 mm |

#10-32 | .200" 5 mm |

| 75-B-T | .750" 19.05 mm |

1/4"-20 | .250" 6.4 mm |

| 100-B-T | 1.00" 25.4 mm |

1/4"-20 | .250" 6.4 mm |