Bal-tec™ Home Ball Check Valves

Ball Check Valves — Ball Poppet Valves — Ball and Seat Valves — Ball Valves — Diamond Impregnated Lapping Ball — Diamond Impregnated Lapping Ball on a Stem

Designing and building a leak-tight ball valve is a rather straightforward task. The use of a precision ball held against a spherical seat to check the flow of liquids or gases is a common design tactic. A precision ball makes the most accurate and by far the least expensive valve-poppet available. Our standard ball bearing materials are hard and wear resistant. Type 52100 chrome alloy steel is very hard at 62 HRC. Balls made from this material are available off the shelf in a large number of sizes and in all AFBMA grades (see AFBMA chart on this website). This material is not corrosive resistant and will corrode easily.

Type 440C is a hard stainless steel that will harden to 58 HRC. It is available off the shelf in a large number of sizes and AFMBA grades. This material is quite corrosive resistant. Type 316 stainless steel is an unhardened stainless steel that is very corrosive resistant. This material is somewhat harder and much more corrosive resistant than the other 300 series stainless steels. It is not very hard, therefore it is difficult to produce very high quality balls. The best grade of this material is only commercially available in grade 100. We can provide quality down to grade 25 on special order.

Tungsten carbide is a cermet that consists of a tungsten carbide powder held together by a metallic binder. The binder is usually cobalt, but chrome nickel which is more resistant to certain chemicals is also used. This material is extremely hard and wear resistant. We stock many sizes of these balls. They are available in all AFBMA grades. This material is quite expensive. There are several Hastelloy® alloy metals that are extremely corrosive resistant and much more wear resistant than 316 stainless steel. This material is expensive and these balls must usually be custom made.

We custom make valve balls from many different materials for special applications: some of these include 17-4 PH, 15-5 PH, Stellite, Inconell, Monel, Kmonel (500), sapphire and several ceramics.

Using the Diamond Impregnated Ball Lap

A lapping process is employed to correct the slight machining errors of the ball seat. Using the proper lapping technique will produce a ball seat that is perfectly spherical within micro inches and will give a metal to metal seal that is leak tight. The common free abrasive lapping process, which uses abrasive powder mixed with oil or grease to form a slurry is a slow, messy process which requires extensive clean up. The abrasive powder on both sides of the ball ball requires the use of special under size balls to end up with the proper spherical radius of the seat. The free abrasive lapping process does not give 100% yield, so every seat must be tested after lapping to cull out the parts that still leak. There is also a tendency for the loose abrasive to embed in the seat of unhardened parts. These abrasive charged surfaces will then degrade the ball.

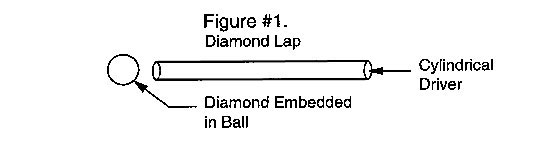

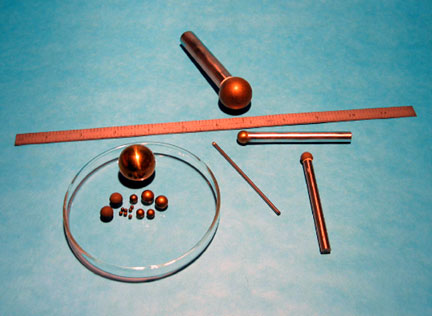

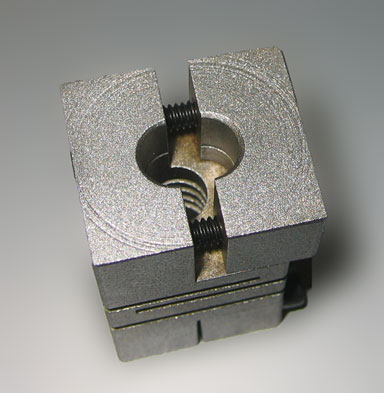

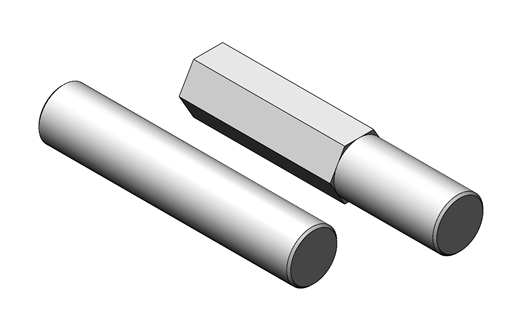

By using the diamond charged ball lapping process, a simple perfectly repeatable process can be developed that will produce a 100% yield or zero leak seats. A better solution is to use our spherical ball-lapping tools. They have a heavy concentration of diamond particles embedded in their surface. These diamond embedded lapping balls are usually glued in a shallow conical cup on the end of a cylindrical pin, to facilitate driving it in the seat lapping operation (see Figure #1.) For high production automated applications, we produce custom lapped tools with a threaded joint.

We can supply the assembled tools to your requirements or just the diamond charged balls for your in house assembly. If you choose to do the assembly in house, the diamond ball lap and the conical cup on the end of the cylindrical driver should be cleaned with isopropyl alcohol before applying the glue.

Just before using the diamond charged lapping tool on the seat, it should be dipped into a low viscosity mineral oil. This oil is to prevent the diamond-lapping tool from galling when it comes into contact with the sharp edge of the seat, and it will carry away the fragments of the metal removed. The lapping tool is slowly rotated against the seat with a little oscillation, either by hand, or with a flex shaft, or some other very light weight slow moving driver.

Normally the coarsest diamond grit used is 9 micron, the most common is 6 micron, which can usually be used for rough and finish lapping, and 3 micron is the finest commonly used. When working with seats made of hard and or brittle materials, the lapping process in one form or another is the only viable approach. In addition to its other attributes, the ball seat lapping process carries almost no risk of personal injury.

To increase tool life, this tool is offered as “armor plated.” The armored plated lapping tool consists of an additional layer of diamond embedding. First a layer of 3 micron diamond is embedded, and then a second layer is applied in either 6 micron or 9 micron diamond. The feedback of our customers' is that this process greatly extends the life of the tool.

Flexible Shaft Coupler Option

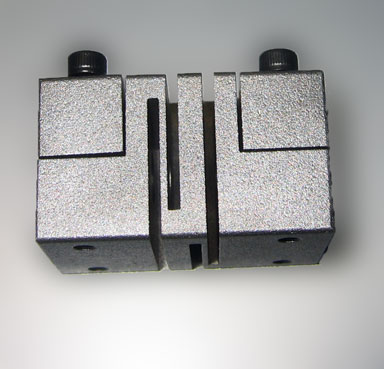

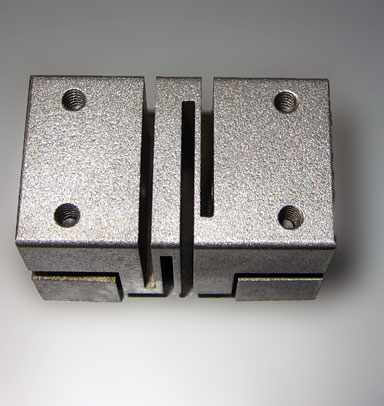

To improve the roundness of the spherical seat generated by the diamond-lapping tool, a flexible coupling should be inserted between the rotating driver and the diamond-lapping tool. A flexible coupling, such as our “Soft Touch,” Part Number FLX-250 ($124.65), should be inserted between the rotary driver and the diamond charged lapping tool.

This “Soft Touch” coupling provides both micro inch perfect self alignment between the diamond-charged spherical lapping tool and the ball seat being lapped. It also provides a cushioned contact between the tool and the part. The vast majority of the wear to the diamond lapping tool occurs in that instant when the lapping tool touches the rough machined edge of the ball seat.

The FLX-250 has a one quarter inch diameter counter bore in each end. The clamping method is not the point contact of a set screw, but the broad contact of a split bar clamp that provides good concentricity and an extremely rigid clamping. Smaller diameter stemmed lapping tools can be used with the soft touch coupling by adding a bushing to go from the standard one quarter inch (1/4”) diameter counter bore down to any smaller diameter needed. Ball lapping tools with larger diameter stems can have the end of the stem reduced in diameter to fit the standard one quarter inch (1/4”) diameter counter bore.

Hex Adaptor for HX-250

A different approach to driving the diamond charged lapping tool is to use one of the hand held, small, battery powered, screw drivers. The device that is being widely used is the inline screw driver that looks a little like a giant cigar, not the one with a pistol grip handle. These devices are equipped with a female 1/4 inch hex drive socket. Our part HX-250 is available made with the female ¼” hex driver of the battery powered screw driver to the quarter inch diameter counter bore of our FLX-250 soft touch coupling. The price is $125.65 each and comes with two parts, the hex adaptor and the cylinder-only shown below.

| Part # | Price |

|---|---|

| FLX-250 | $125.65 |

| HX-250 | $17.00 |

The Conical Seat

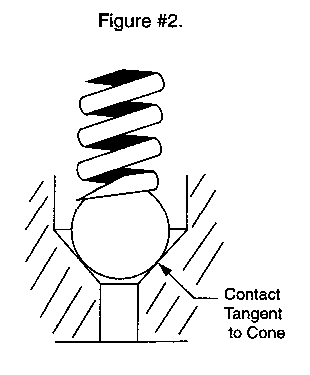

A widely used ball seat design consists of an internal conical surface with a through hole. This design has the advantage that the ball will self center as it moves toward the seat. There are two functional variations of this design. In the first, the contact of the ball is tangent to the cone. Machining tolerances for this design can be liberal as the ball contact only needs to fall somewhere along the conical surface (see Figure #2.). For this design to work well, the cone must be machined very round.

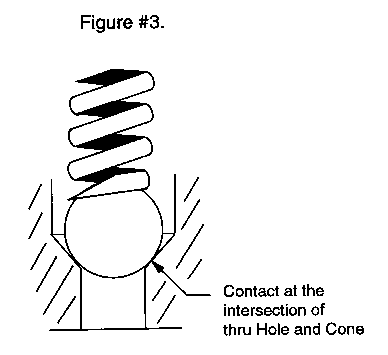

The second version of the conical seat has the ball making contact right at the intersection of the cone and the through hole. Using the same conical angle this design yields much higher sealing forces. Therefore, a leak free valve is easier to produce, while still maintaining the good self-centering of the ball and the quick reaction of the valve. The machining tolerances for this design are quite tight, as the ball must end up exactly at the intersection of the cone and the through hole (see Figure #3). This design requires a very round cone and through hole and good concentricity between them.

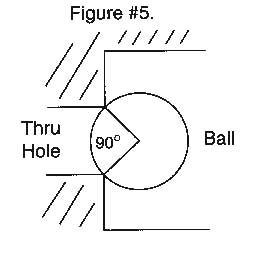

A design question that must be answered is what should the angle of the conical seat be? There are several factors involved. The steeper the angle the better the balls self-aligning tendency will be. The steepness of the angle must be tempered by the fact that the ball must be released from the seat when the flow reverses. The flatter the seat angle the crisper the ball release will be, but as the included angle increases the sealing quality is reduced. The majority of ball seats have an included angle of 90 degrees, which is 45 degrees per side, or very near it.

The Flat Seat

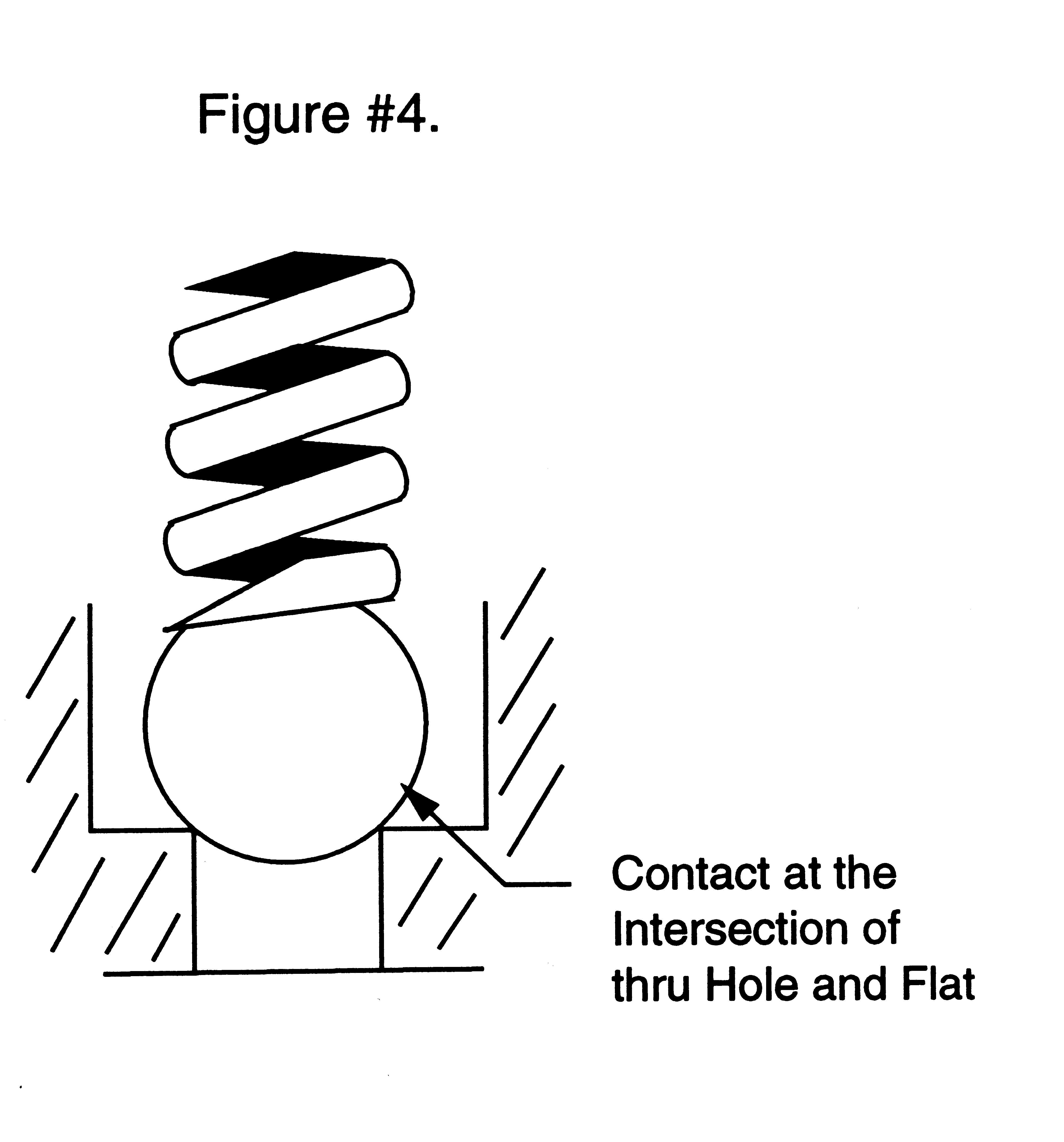

The main alternative to the cone with a through hole is to use a flat seating surface with a through hole. This design will give a much higher elastic load on the seat, which in turn will result in a better seal at lower pressures. An additional advantage is that the flat surface and the through hole are both easy surfaces to generate to high levels of quality. This is very important because any errors in flatness, any errors in roundness and any error in squareness will reflect directly into the quality of the sealing surface. The main drawback of this design is that it lacks the self-centering feature of the cone (see Figure #4.)

Summary of Ball Seat Design Constraints

The ball contact angle on the flat seat design is determined by the ratio of the through hole diameter to the ball diameter. The higher up on the ball, that is the steeper the included angle, the better the seal, but the poorer the balls release function will be. Design wisdom seems to have settled on 45 degrees per side or a 90 degrees included angle (see Figure #5.).

Tri-Point Seat

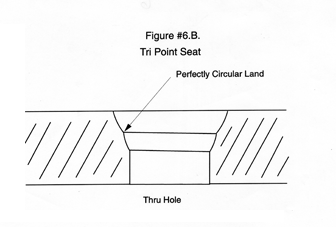

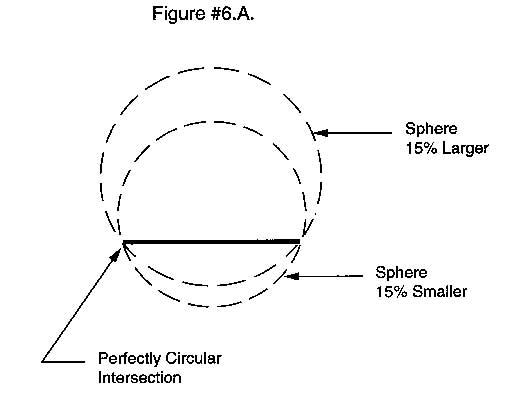

The ultimate in zero leakage ball seat designs is the Tri-Point Seat. A significant feature of a sphere is that it has a single radius in all directions. This uniquely perfect geometry is used to form the ultimate ball seat. At the intersection of two concave spherical surfaces, of two different diameters, there will occur a perfectly circular land. There are no concentricity errors and there are no squareness errors. The two concave spherical cups are almost always generated by lapping. In practice the two spherical cups are usually 10 to 15 percent larger than and smaller than the valve ball. A very narrow spherical land ( .002 to .005 inch [ 0.05mm to 0.13mm ] wide), that is the same radius as the valve ball is usually lapped on the land at the intersection of the two spherical cups (see Figure #6.A.). It is important that the width of the spherical lands be limited to ( 0.002" to 0.005" ) [ 0.05 mm to 0.13 mm ], if true zero leakage is to be achieved. The material used in these seats is usually a high tensile, high hardness metal. Because very high Hertzian Elastic forces result from this design, very low pressures can be sealed to zero leakage. Even Hydrogen and Helium gas can be controlled with this ball seat design.

For the very same reason that it works so well at low pressure, this seat is limited for high-pressure applications. As the pressure on the ball goes up, the elastic limit of the seat material will eventually be exceeded and the sealing land will be brinelled into a broad spherical cup that will no longer seal. A high force may cause cracks in the seat area.

Elastic Compliance

When achieving an acceptable seal is a real problem, the rule that states, “some elastic deformation of the seat is required to achieve this zero leakage," must be emphasized. How does the belt comply with your out of round body? Ball seats function on the same principals.

Even with the best achievable geometry and the finest surface finish of the ball and seat, it will still have some leakage. The inhomogeneous crystallographic structure of the metals is huge when compared with the atomic dimensions of gases and liquids. In order to totally eliminate all leakage, enough force must be applied to the ball to achieve mechanical compliance between the contacting surfaces. A small amount of Hertzian Elastic Deformation is required to close the tiny undulations in the surfaces of the ball and the seat.

When the ball check is in the sealing mode, the pressure of the liquid or gas, will be forcing the ball down against the surface of the seat thus increasing the sealing force. The somewhat illogical fact is that very low pressures are much more difficult to achieve a zero leakage seal than higher pressure.

Design Parameters

Designing a ball check valve starts with the diameter of the through hole. The diameter of the through hole is determined by the required flow rate, which is in turn dictated by the Reynolds' number, the fluid pressure and the Kinematic viscosity of the solution or gas. Charts and graphs that will give close estimates of the through hole diameter are available in Mechanical Engineering Hand Books. The seat configuration can be chosen by applying logic to the earlier discussions. The ball diameter is dictated by the through hole diameter, the seat configuration and the desired contact angle between the ball and the seat.

The Likely Results of Press Fitting Ball Seats Into a Housing

In order to provide a zero or near zero leak rate, the spherical seat of a ball valve must be accurately lapped within micro inches (tenths of micro-meters). Our diamond charged lapping tools will generate this quality almost automatically, and it only takes a matter of seconds. With such a high degree of geometric accuracy required to achieve a leak tight seal, it is not surprising that press fitting a lapped seat into a housing can cause serious problems.

If press fitting is to be accomplished successfully, serious restrictions must be adhered to. The outside diameter of the seat should be precision ground to provide excellent roundness. The housing should be precision bored or even better honed very round. The seats should be designed to be very robust and the least possible press fit or interference should be used. If a press fit must be used, can the seat be diamond lapped after it has been pressed into place? Alternatives installation techniques, such as gluing or of using threaded parts and resilient seals should be considered in the design.

Spring Preload

The majority of ball-check valves have at least a light spring pressure forcing the ball against the seat and when the ball check forms a relief valve the spring may be substantial. In most spring loaded applications, the force is supplied by a helical compression spring. For small spring loads, the end coil of the spring sits directly on the surface of the ball, on the side opposite the ball seat (see Figure #3.). When applying a heavy force, a spring guide plate is added to the design. This device has a spherical or conical cup that fits over the ball on one side and an extended boss on the opposite side that locates on the inside diameter of the spring.

Weight of Large Balls

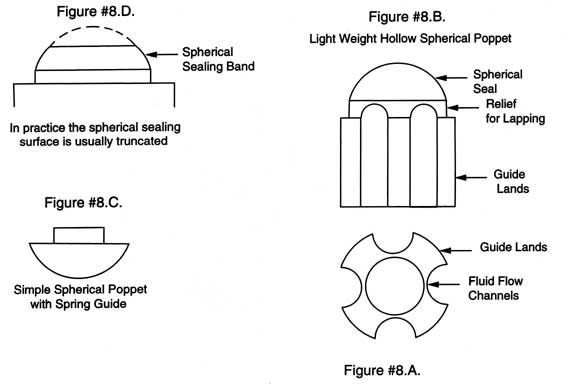

The mass of a specific diameter ball is fixed. As the design parameters of the valve are changed, to accommodate a larger flow rate, the diameter of the ball must increase. The volume and therefore the mass of a ball varies as four times pi times the radius cubed, over three { 4 * 3.14 * (r^3) / 3 }, so any increase in the ball diameter has a dramatic affect on the mass of the ball. An increase in the mass of the ball will cause the reaction time of the valve to slow down and the increased inertia of the large ball will pound the living daylights out of the seat. By substituting a large, lightweight, spherical tipped poppet for the massive sphere, the good self-alignment and excellent sealing qualities of the ball are preserved with a fast reaction time and only moderate wear of the components (see Figure #8). We can manufacture the spherical poppets for you, or we can precision lap the spherical end of the poppets you supply to a high degree of perfection so that they will form a seal comparable to a high quality ball.

Small and Very Small Ball Valves

As the diameter of the ball decreases, the actual resulting force on the ball seat goes way down. Reiterating the fact that you must have some elastic compliance between the ball and the seat to achieve a zero leakage seal, the overall quality of the seat and the ball itself must be much better for very small valves.

On very small ball valves the roundness and surface quality of the through hole must be better than normal. One of the tactics here, is to “Ballsize” the hole. This means pushing an oversized ball (usually Tungsten Carbide for small holes) through the hole. Usually a one thousandths of an inch (0.25mm) interference is about right. If the seat is hardened, the ball sizing should be done before the seat is heat treated. Ballsizing will dramatically improve the surface texture and the roundness of the hole. See our technical paper on “Ballsizing” that is on this website.

For very small ball seats, the design used is almost always the intersection of a hole and a flat surface. The design is used to maximize the stresses on the seat to induce Hertzine elastic conformance with the ball. On small and very small Ball Seats, the mechanics of the lapping process can be very complicated to mechanize. Even when large numbers of units are being produced, the actual lapping process is often done entirely by hand. The stem of the lapping tool is simply held in a pin vice, and the diamond charged lapping tool is dipped in oil, then the tool is applied to the seat with a rotating and oscillating motion.

If there is still a leakage problem, the quality of the ball used in the valve should be scrutinized. In some problem cases, the top surface of the ball seat may be machined as a male cone instead of flat. This cone is usually limited to about 15 degrees, but in extreme cases it may need to be up to 30 degrees. If none of these simple approaches will work, you can always go to the “tripoint seat” as previously discussed. The “Tripoint Seat” is sophisticated to produce, but it will perform when nothing else will.

Plastic Balls

In a closing note, we will look at using balls made of highly resilient materials such as rubbers and plastics. Rubber still finds some applications in low-pressure devices, but it has been replaced by much less expensive plastics in most applications.

Density of Plastic

One common consideration is the specific gravity or mass of the plastic ball material. Polyethylene and polypropylene have specific masses of approximately .98 so they will just float in water. Polyethylene is slightly softer and more resilient, while polypropylene is harder and tougher. Both materials have good resistance to organic solvents as well as moderate acids and bases. Both are low cost materials that we stock in most sizes.

For heavy-duty applications, Nylon is the hands down favorite. It is fairly hard, very tough i.e. wear resistant and we stock finish ground balls in most sizes. Nylon is resistant to most organic solvents as well as mild acids and bases. Nylon does have a problem in aqueous solutions, as it is slightly hygroscopic and will swell about 1/4 of one percent ( 0.25% ).

Click to see our Nylon ball stock in our shopping cart.

Teflon

For very high and very low temperatures PTFE is the obvious choice. PTFE has a high density, i.e., it is heavy. We stock precision ground PTFE balls in most sizes. PTFE is not cheap, it is several times as expensive as most other plastics. There is another problem, PTFE can cold flow under heavy pressure and may not come out of the seat after a long exposure to a high-pressure condition. Care must be exercised in the seat design when using this material. A ball tangent to a rather large conical angle is the normal design.

Click to see our PTFE ball stock in our shopping cart.

Measuring the Width and Quality of a Ball Seat

The "Smokey Ball" Technique

When there is little or no contact between the the lapped spherical land that forms the ball seat and the the material of the seat itself, it is difficult or even impossible to evaluate the quality and the width of the land. This is a common problem for stainless steel seats, but is really severe on translucent or transparent materials such as plastics and ceramics.

The simple solution is to "smoke" a ball on a stem. If you hold a standard ball plug gage over the flame of a candle, the ball will acquire a very thin coating of carbon black. By barely touching this "smokey ball" to the surface of the spherical ball seat, the carbon black will transfer and the seat will become highly visible. A precision ball of the correct diameter mounted on a stem is available, see "Ball Plug Gages." This precision ball can also be purchased with an engraved handle for convenience and identification.

Testing Leakage

The simplest test for a ball check valve is to pressurize the valve and measure the leakage. For hydraulic valves, it is not uncommon for the test specifications to give a maximum number of drops per minute; and for gas, the number of bubbles, at a given pressure that is an acceptable leakage. This method may not be appropriate for several reasons. The leakage may be so slight that it will take a long test period to measure it. The small amount of leakage may get lost in the valve body passages. It may be very expensive to find out that a very complex, completely assembled product must be reworked.

Bubble Test

A faster, cleaner, cheaper and more sensitive method is to pressurize the valve with a compressed gas (frequently shop air) at a given pressure, while submerging the valve body in a tank of tap water. The quality of the valve is evaluated by counting the number of bubbles that escape in a given span of time. It should be noted that corrosion prone materials might rust due to submersion in the water bath, so an alternative liquid may be required.

Vacuum Test

Another very sophisticated approach is to pull a high vacuum down stream of the ball check valve. Then to close a zero leak valve to trap a fixed volume container at vacuum. By measuring the time for the decay of the vacuum to a given pressure, the quality of the ball check valve can be quickly and accurately evaluated. This is probably the fastest and most reliable test that can be performed. After establishing acceptable parameters, this test can be used in highly automated environments. We recommend the JRM Vacuum tester. See: http://www.delucatest.com/access.htm

Mass Spectrometer

We produced metal-to-metal ball check valves for the fuel cells of the Apollo Space program. The Tri-Point seat was used in these valves. The system performance was so critical that the leakage was measured with a mass spectrometer. This test had the capability to detect even one molecule leakage of the helium gas used for the test.

Durability

During the design and in the manufacturing process, the prime criterion for ball valves is the final leakage of the finished product. In this regard, a seat formed at the intersection of a through hole and a flat annular ring will give low or zero leakage, and one with a top surface that forms a positive male cone will leak even less. But, how long will these highly stressed zero leak seats last?

A valve that has the ball sitting tangent to a conical seat is a more durable design. This design is more critical in that the manufacturing is much more difficult. It is difficult to machine a round conical surface. It is difficult to control the angle and the depth of the cone so that the ball contacts the center of the cone. The contact angle between the seat and ball is important. A ninety degree conical angle is typical, but a steeper angle will seal better, and a flatter angle is more durable.

The conical angle will lap into a wider than desired spherical land much faster so it is more difficult to keep the required narrow land to produce the desired high stresses for a low or zero leak valve. The durability of a ball valve may have a lot to do with the choice of materials used. Up to a point hardness is desirable. A fine, homogeneous, grain structure is important. A material that tends to be more a mixture of elements, than a homogeneous alloy may have good corrosion resistance and high temperature properties, but will quickly erode the mating part.

Materials that use the precipitation of microscopic particulate to strengthen and harden the alloy are another undesirable valve material. Plastics that use glass or ceramic particulate to improve their physical properties are a problem going somewhere to happen. With this crazy new patent system, that we have, we do not take any responsibility for someone's supposed claim to ownership of basic designs, most of which have been used for a hundred years.